Tagged Under:

A Commitment to Conservation

Our sustainable practices are aimed at preserving precious natural resources.

As the world’s leading (and largest) manufacturer of musical instruments, Yamaha has a singular responsibility to the environment, and it’s one we take very seriously.

Our company has long been committed to sustainable practices that balance social and environmental concerns. We are constantly striving to conserve resources in a variety of ways, including reducing product size and packaging, and we are constantly developing alternative materials that can be substituted for scarce timber for use in our products, such as biomass-derived resins. In addition, our production facilities have established sophisticated recovery/separation procedures to reduce waste produced at factories and offices and promote recycling. The Yamaha Group in Japan, for example, has a recycling rate of about 99%.

Our approach is multi-faceted but focuses primarily on four areas: Green procurement, initiatives for timber resources, water conservation practices, and the creation of “Yamaha Eco-Products.” Let’s take a closer look at each of these.

Green Procurement Policy

The Yamaha Green Procurement Policy ensures that we obtain materials from suppliers that promote environmentally-friendly management, with a priority on materials that have a low environmental impact. We procure products, parts, and raw materials that have eco-friendly features such as reduction of substances of concern, conservation of energy and prevention of global warming, and recycling of resources and conservation of materials.

Initiatives for Timber Resources

Many Yamaha products, including pianos as well as string, percussion, and woodwind instruments, require a primarily wood construction for acoustic reasons. Large amounts of timber are also used when making electronic musical instruments and speakers due to the merits of wood in terms of acoustic performance, function, design and texture.

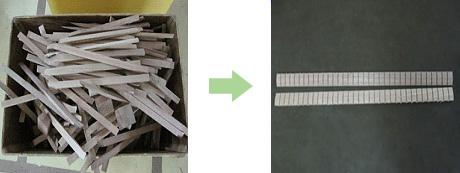

We are working to reduce waste by improving the yield ratio in timber processing, and by reusing and recycling wood chips. We make a practice of selling offcuts to building material makers as raw material for hardboard, in addition to using them to create other product components. As an example, some timber offcuts previously disposed of as waste are instead reused as angle rafters (reinforcing materials inside guitar bodies).

We have also established a formal Timber Procurement Policy to set the direction of our timber usage in order to better conserve this precious resource, as well as ensure its availability for continued use in the future. This policy states the following:

- We will procure timber that has been legally logged and traded from clearly identifiable sources.

- We will give priority to procuring timber that has undergone reliable forest certification.

- We will obtain sufficient confirmation of the sustainability of any endangered tree species from which Yamaha obtains wood materials.

- We will not procure timber derived from logging that destroys ecosystems, or from logging of High Conservation Value Forests.

- We will not procure genetically modified tree species.

- We will confirm that our timber procurement practices do not have any adverse effects on local communities, such as violation of the rights of indigenous peoples that occur in the course of logging and trading.

- We will work to transition to the procurement of wood-based materials that utilize substances such as planted wood and recycled wood, and therefore make efficient use of resources.

In addition, Yamaha suppliers are encouraged to observe a formal Code of Conduct, which clearly stipulates points related to the harvesting and trading of timber resources.

Together, these initiatives aim to maximize the use of timber as a first-rate recyclable resource without waste. As an example, in 2016, Yamaha began investigating African Blackwood, an important material used for woodwind instruments, specifically regarding the ecology, amount of resources, and forestry management status in the United Republic of Tanzania where the timber was being procured at that time. This tree is classified as Near Threatened by the IUCN (International Union for Conservation of Nature) Red List and in recent years the resource volume has been trending down. These investigations showed that sustainable procurement is possible with proper management and so we aimed to construct a business model which could sustainably use African Blackwood as a material for musical instruments. In 2018, we began tree planting activities for African Blackwood and formed a partnership with local timber producers to explore the efficient use of existing resources.

Another important development in March 2016 was the creation of circulating-type “Piano Forests” in Japan, in cooperation with government agencies and a local manufacturer. This is aimed at preserving the forests and to ensure a stable supply of high quality Picea glehnii timber, used in the manufacture of piano sound boards.

In addition, Yamaha is proactively introducing wood cultivated specifically for industrial purposes on planned plantations as well as certified wood, which is properly managed so that the lumbering process does not harm the forest or the ecology. These measures aim to use the excellent renewable resource of trees on a sustainable basis. We are also focused on developing alternative materials that accurately reproduce the sound quality of rare wood materials best suited for instruments.

Preservation of Water Resources

Like all manufacturers, Yamaha uses water to wash products and cool facilities. However, we do not have large-scale production activities in areas where water resources are poor, so we believe there is minimal impact on the environment due to such usage. In addition, we continually conduct surveys and evaluate factors such as physical water stress, water quality and regulatory risks related to water resources.

Significant amounts of water are used in the plating and washing process during the manufacture of wind instruments. Accordingly, since the early 1970s, Yamaha has been recycling cooling water and wastewater using reverse osmosis, as well as actively pursuing policies to prevent leakage in water facilities.

Yamaha Eco-Products

Established in 2015, the Eco-Products program is a Yamaha initiative aimed at certifying environmentally-friendly products that meet certain standards, such as:

- Reduction in contained harmful substances and volatile organic compounds (“VOCs”); for example, the use of lead-free solder in all brass and woodwind instruments.

- Employment of alternatives to rare woods by switching to materials that contribute to sustainability.

- Promotion of saving and reuse of resources.

- Reduction in energy consumed during usage.

The aim of this program is to provide customers with environmental-related information and facilitate their identification of our products meeting these standards when they select items to purchase.

To date, over 600 products have met these guidelines and another 30 will receive the Eco-Products designation in 2019. Some examples include plant-based Ecodear® plastic recorders, as well as MusicCast networked Consumer Audio products, which have low networked standby power consumption. In addition, many of our PA powered mixers (such as the EMX Series), powered speakers (such as the DBR Series, DXS Series and DXS XLF Series) and complete powered PA systems (such as STAGEPAS products) fall into this category due to their usage of high efficiency amplifiers.

We only have one planet to live on! Let’s celebrate the wonderful resources nature has provided us with, and to resolve to do all we can to preserve those resources for generations to come.

Click here for more information about the Yamaha commitment to sustainability.