Reimagining the Vibraphone

A level of detail that leads to better playability and a more consistent sound quality.

The vibraphone (sometimes known simply as “vibes”) has only been around since the early 1900s, so it’s a relatively new instrument. Nonetheless, it had a major impact on the sound of music during the mid-20th century, and is still commonly used in jazz, where it often plays a featured role.

While the instrument resembles a marimba or xylophone, a vibraphone employs metal tone bars made of alloy that are suspended over a resonator with a motor-driven fan at the top of each resonator tube that creates a vibrato effect — hence the name vibraphone.

The vibraphone also has a sustain pedal similar to the one found in a piano. The pedal operates a felt-covered damper bar, which moves up and down against the tone bars. When the pedal is up, the damper touches the tone bars to produce a muted sound. When the pedal is down, the damper is pushed away, and the tone bars ring out (i.e., sustain) for a few seconds or until they’re muted by the damper being released by the pedal. (Click here for more information about the components of a vibraphone.)

The growth of school music programs in the 1950s sparked by the post-war baby boom caused greater demand for musical instruments in general, including mallet percussion instruments such as the vibraphone. Over time, the vibraphone was incorporated into collegiate-level percussion performance education. It is now a standard member of the modern percussion section for orchestras and concert bands at all levels of instruction.

Early models of Yamaha vibraphones included several unique features for young players, including height-adjustment capability, non-graduated bars, a variable speed motor and silver matte bars. After several years in development, the YV-2030MS and YV-3030MS models introduce new innovations to make the musical journey of young percussionists a more meaningful experience. These models offer a level of performance that satisfies a broad spectrum of users, from beginning band to high school students.

Here are some of their main features:

Gas Spring Height Adjustment

Both the YV-2030MS and YV-3030MS incorporate a gas spring height adjustment mechanism, making it easier for players of any stature to set the instrument to the ideal height.

Previous models used a sliding height-adjustment mechanism that required a coordinated effort by two people. In contrast, the gas spring height-adjustment mechanism only requires one person for safe, easy height adjustment. The improved operation of this system also allows for quick adjustment from player to player during a concert or rehearsal.

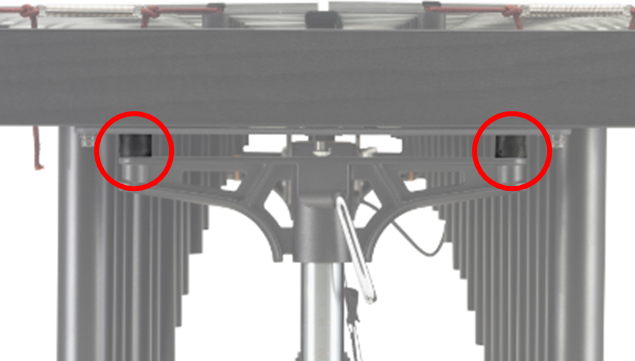

In addition, there are two vibration-damping rubber joints mounted below each side frame, circled in red in the illustration below. These components make height adjustment even easier by eliminating the need to keep the instrument level while adjusting its height. They also reduce floor noise that can occur when the instrument is played.

Damper Belt

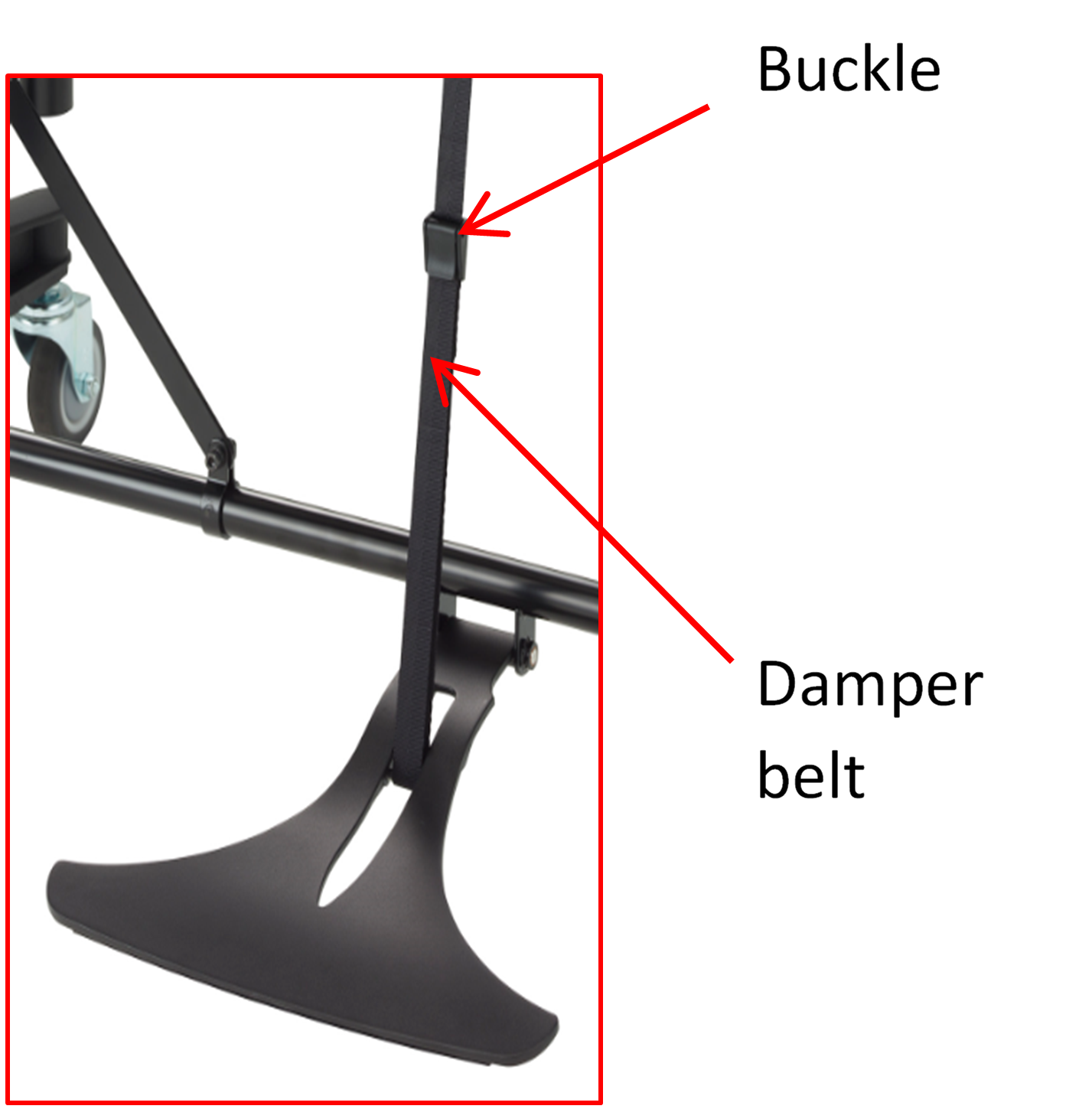

On previous models, the damper bar and pedal were linked by a metal rod that could be accidentally bent if a user attempted to adjust the instrument’s height without first loosening the rod’s wing bolts. In the YV-2030MS and YV-3030MS models, the metal rod has been replaced by a belt to eliminate this problem — an innovation inspired by the design of Yamaha drum set pedals. Since the wing bolts are replaced by a buckle, there is no chance they will be misplaced or lost. The use of a belt also ensures that slippage cannot occur when the damper pedal is pressed.

Damper Bar

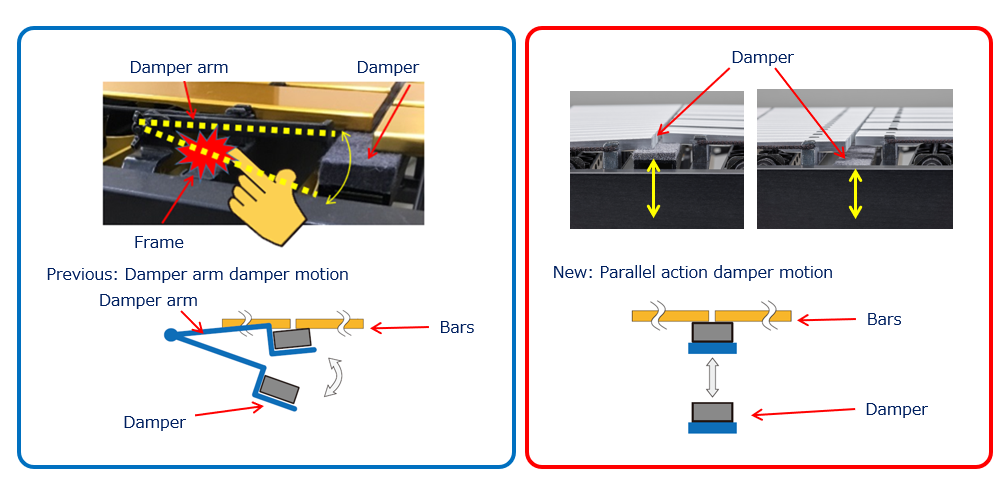

Compared to conventional damper mechanisms that use a pivoting damper arm, the redesigned mechanism used in the YV-2030MS and YV-3030MS models allows the damper bar to move perpendicularly to the natural and accidental tone bars. This allows all the bars to have an even damper and release at the same time. In addition, since there is no longer a damper arm, there is no danger of getting fingers caught in the damper arm mechanism.

Bar Material

A consistent touch in vibraphones not only enables a larger dynamic range, but also imparts a warmth to the tonality. The new bar material employed by the YV-2030MS and YV-3030MS produces an even gentler tone that blends well with other instruments in ensembles. These bars are made of the same aluminum alloy used in Yamaha celestas.

Variable Speed Driver

A common problem with vibraphone motors is that they can be quite loud; over time, they can even create an unwanted noise. YV-2030MS and YV-3030MS motor noise has been reduced by approximately 25% compared to previous models. This has been accomplished by using an ABS plastic material for the motor box rather than steel.

Additionally, the vibraphone variable-speed driver for the YV-3030MS includes a pause memory feature previously available only on high-end models, significantly enhancing the overall value of the instrument. This allows the fans to always stop at the memorized position when paused for non-vibrato playing, ensuring that consistent volume is maintained even when the driver is stopped and started multiple times.

This level of detail in Yamaha vibraphones leads to a greater level of playability, more consistent quality of sound and the removal of unwanted frame and motor noise — important benefits for both students and music educators alike.

Check out these related blog articles:

What’s the Difference Between Vibraphone, Glockenspiel and Chimes?

Click here for more information about Yamaha vibraphones.