A Brief Guide to Piano Tonewoods

Learn about the woods that are used to make pianos.

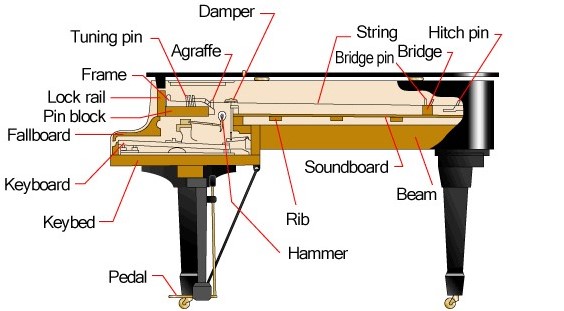

The acoustic piano is an incredibly complex musical instrument, with thousands of moving and resonating parts. The vast majority of those parts — up to 85% — are made of wood.

Even with the benefit of centuries of design history and refinement, piano makers have the important task of choosing those woods that provide just the right properties and characteristics to deliver a pleasing sound. Let’s take a look at the tonewoods commonly used in pianos, and the reasons why they are selected.

The Soundboard

By far, the most important part of the piano as it relates to sound is the aptly named soundboard, which is always made of wood. In fact, without a soundboard, you would barely hear anything at all! After a key is depressed and the corresponding hammer strikes the string, the soundboard’s job is to vibrate sympathetically and amplify the sound coming from the strings. For that reason, it’s almost always made from a soft wood. Most piano manufacturers use spruce for their soundboards, but cedar, alder or ash are also sometimes utilized. The main differences in the soundboards used in grand pianos versus upright pianos is their size and shape.

Yamaha has their own lumber mill and processing facility, Kitami Mill, located in Hokkaido, Japan, a region that has the perfect climate for wood treatment. There, the company’s highly skilled artisans inspect and choose only the finest cuts of wood, with only around 10% designated for use as soundboards. Depending on the model, Yamaha uses European, Asian or North American spruce. These woods are chosen because of their pliable nature, which gives them the ability to keep vibrating for a long time, even after the long decay of the struck string dies away. They also slightly attenuate the highest frequencies/harmonics, which helps to produce a warm, pleasing tone.

The wood used for constructing soundboards is first cut into long planks before going through various stages of drying. Typically, it’s air dried for anywhere from six months to two years, then dried further in a kiln. (The kiln in the Yamaha Kitami facility is believed to be the largest in the world.) This process is overseen by experts, who constantly check the wood for moisture and eveness of drying; without this monitoring, the wood may be susceptible to warping and cracking. Once the drying stage is complete, the planks are glued together and joined with wood strips called ribs. These help reinforce the wood and distribute the vibrational energy throughout the case and into the performance space.

The Bridge

The vibration of the strings are transferred to the soundboard by blocks of wood called the bridge. There are actually two different bridges in a piano: a long bridge for the middle and upper strings, and a shorter one for the bass notes. There are hundreds of pounds of pressure exerted on these bridges by the taut piano strings — especially the very thick bass strings — and withstanding that pressure and transferring the vibrational energy without any loss requires a very dense, hard wood. For that reason, most piano makers use maple, or a mix of maple and beech for their bridges; Yamaha uses hard maple, as it is 25% denser than regular maple.

Related to the bridge and strings is the pin block, which holds the pegs that the strings are wound around. Again, hard woods are essential here, and Yamaha uses maple for its density and strength. While most pin blocks use a laminated wood process for increased grip, Yamaha is unique in that they also use threaded pins for improved stability.

The Rim

The body of the piano is called the rim. Because the inner part of the rim (the inner rim) is attached to the soundboard, it effectively acts as an extension of the soundboard, reacting to the vibrations of the strings by bouncing them back — a critical part of the amplification process that has a big impact on the tone of a piano. The outer rim encases the inner rim and soundboard and adds further reflection of the tone, as well as becoming the outer cabinet of the piano after being covered with a final cosmetic wood veneer.

Piano rims are created from 6 to 10 layers of wood that are glued together lengthwise. For a grand piano, those layers are glued and laminated together to make a single long board, which then gets bent into the distinctive grand piano shape. (The process of constructing a grand piano rim is one of the most interesting aspects of the craftsmanship that goes into building a piano.) The process is a bit simpler when making an upright piano. Since the rim shape in those types of pianos is a rectangle, it can be constructed from four thicker blocks fitted together.

Piano rims are often made of maple and/or maple and mahogany laminate, though sometimes spruce is used. The rims in Yamaha pianos are mostly made of hardwoods such as mahogany or beech, with hard maple and even ash used at times. In some Yamaha grand piano models, the wood is specially aged after traditional drying using a patented A.R.E. process (Acoustic Resonance Enhancement) process, which helps to increase the wood’s resonant qualities as if it were aged for a hundred years or more … but accomplished in a fraction of the time. This type of treatment has been used to improve the sound of guitars and violins, but Yamaha is the first manufacturer to apply it to piano design.

The Keys and Hammers

The types of wood used for piano keys and hammers are particularly important because they provide important tactile, and therefore emotional, feedback to the player. The keys, for example, serve as the main interface between the player and the instrument. They need to provide a good “feel,” which means they must have some mass, and offer just enough resistance to allow the pianist to control the sound, but they also must be light enough to provide very fast repetition response. For similar reasons, the wood used for hammer shanks needs to have a certain amount of elasticity and resonance — something that’s especially noticeable when doing fast repetitions.

Many manufacturers use fir, sugar pine or bass wood for their piano keys; Yamaha uses Sitka or Japanese spruce — the same wood as is used in the soundboards of certain model pianos. These are more expensive than other woods, but are virtually free from warpage and have an excellent strength-to-weight ratio that provides a fast but durable action.

Light woods such as walnut, mahogany and hornbeam are commonly used for hammers. The lighter the wood, the faster the hammer can accelerate, so in general those kinds of woods are preferred.

A Commitment to Sustainability

Yamaha makes a conscious effort to operate in ways that do no harm to our environment. This sense of personal responsibility permeates every aspect of the company’s design and manufacturing processes. For example, every year their Kitami Mill holds a tree planting festival, adding more Sakhalin spruce to their forest so they can maintain a zero-loss of deforestation. In addition, working with local universities, Yamaha invests in research to help increase the yields per tree of many of the species it uses from around the world. Climate change is, of course, also having a major effect on tree growth and Yamaha is working with suppliers to safeguard the quantity and quality of the woods being grown.

Click here for more information about Yamaha grand pianos.

Click here for more information about Yamaha upright pianos.

Click here to locate your local authorized Yamaha piano dealer.