Reimagining the Way Student Violins Are Made

Computer-assisted craftsmanship makes Yamaha student violins easy to maintain

The violin is one of the oldest instruments still in wide use all over the world. In fact, the earliest versions of these stringed instruments closely resemble what you see being played in your community’s orchestra today. The traditions of violinmaking have been passed down for generations, and some of the most sought-after vintage violins are from the 18th and 19th centuries.

The growth of school music programs in the 1950s sparked by the post-war baby boom caused greater demand for musical instruments in general, and violins in particular. Unfortunately, the age-old and venerated tradition of skilled luthiers making violins by hand gave way to more automated processes in the form of woodworking machinery to speed production and meet the increased demand. The result of these processes was a flooding of the market with violins that were out-of-tune, hard to play, and fragile. Ever since then, many students — and their parents — have had to choose between a cheap violin that may last only a few years and a very expensive, luthier-made instrument.

Nearly a decade ago, Yamaha sought to bridge the gap by providing those looking for a high-quality, durable student violin with an affordable instrument that had excellent playability and warm sound to inspire the next generation of young musicians. The result of those years of development is the YVN Model 3 family of violins, which embody the most significant technical advancements in violinmaking since the advent of the instrument hundreds of years ago.

Building upon methods pioneered by Yamaha in the manufacture of percussion and wind instruments, the YVN Model 3 is built with the accuracy normally associated with much more expensive hand-built models … and, as a bonus, they are more environmentally friendly.

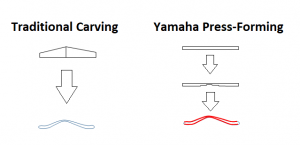

Traditional methods of violinmaking involve the carving of solid wood into the tops and backs of the violin, yielding wasted material and inconsistencies caused by climate and material variations. The YVN Model 3utilizes the thickness and arch shape of traditionally made instruments, but its proprietary graduated “press-formed” spruce top offers exceptional resonance, and the three-layer construction of the tops and backs uses just one-third of the amount of wood previously consumed. These techniques give the instrument more consistency as it ages and when experiencing environmental changes such as alterations in temperature and humidity.

Whereas luthier-built violins rely on handcrafted techniques to build a violin, the YVN Model 3 is made with computer-assisted craftsmanship. This ensures that these violins are easier to service than traditional string instruments. Because every part — including those that have been historically difficult to repair — is constructed with a high degree of precision, repair and replacement are simple tasks, making it both faster and more cost-effective to keep a Model 3 in playing condition. Gone are the days when custom work was required to fix simple violin mishaps!

Click here for more information about the YVN Model 3 family of violins.